How to Draw Oc Curve for Double Sampling Plan

After reading this article you volition learn virtually:- 1. Introduction to O.C. Curves two. O.C. Curves for Single Sampling Plan iii. O.C. Curves for Double Sampling Programme 4. Zones.

Introduction to O.C. Curves :

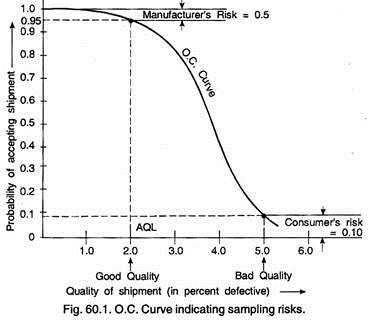

O.C. curves quantifies manufacturer's (producer's) adventure and consumer'due south (purchaser'due south) risk. This is a graph of the percentage lacking in a lot versus the probability that the sampling plan will accept a lot.

An O.C. Curve drawn for sampling plan of due north = 300 and C = ten at Fig. 60.ane indicates the following:

AQL = 0.02 or two%

Manufacturer's risk = 0.05

Consumer's take chances = 0.10

LTPD = 0.05 or more defectives.

All practical sampling plans have an operating characteristics curve, briefly called O.C. curve.

Following points need emphasis regarding O.C. curves:

(i) At that place is some chance that good lots volition be rejected.

(ii) There is some chance that bad lots will be rejected.

(three) These risks can be calculated past the theory of probability and depends on the number of samples inspected, the acceptance number, and the percent defectives in the lot offered for sample inspection. Given the amount of risks which can be tolerated, a sampling plan can be devised to meet these requirements.

(four) The larger the sample used for inspection, the nearer the O.C. bend approaches the ideal. Still beyond a certain point, the added price in inspecting a big number of parts far exceeds the benefit derived.

In any acceptance sampling program, three parameters are specified. The first parameter is number of articles N in the lot from which sample is to exist drawn. The second parameter is the number of articles n in the random sample drawn from the lot, and the tertiary is the acceptance number C.

This acceptance number C is the maximum allowable number of defective manufactures in the sample. If more than than C defectives are found in a sample the lot is liable to be rejected. Since the lot size has piddling affect on the probability of acceptance, therefore lot size is mostly ignored in deriving a sampling programme.

O.C. curve of an acceptance sampling plan (i.e. for a detail combination of n and C) shows how well the sampling programme discriminates between good and bad lots. In social club to examinationine the suitability of an acceptance sampling programme, it is necessary to compare their performance over a range of possible quality levels of the product.

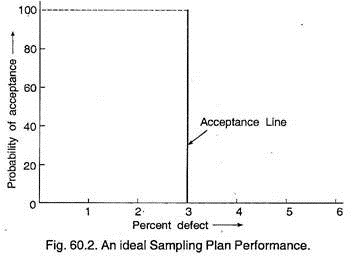

The graph of this operation is known as operating characteristic curve. Fig. threescore.2 below shows an platonic O.C. curve where it is desired to accept all lots having 3% or less defectives, and to decline all lots having more than 3% defectives.

In this curve, all lots with less than 3% defectives accept a probability of acceptance of 100%, while all lots with more than iii% defectives have a probability of acceptance as 0%. However such a plan does not exist in reality.

O.C. Curves for Single Sampling Plan :

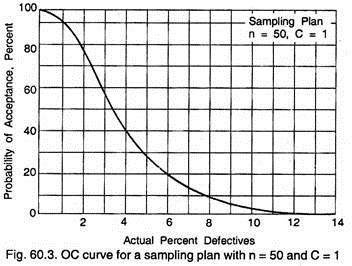

Graph 60.three is an OC curve for a sampling plan with north = 50 and C = 1.

Graph shows the probability of credence of lot for various values of percent defectives in the lot. Suppose, if the actual bad quality were one percentage, samples of n = 50 would accept the lot as satisfactory about 94 percent of the time and reject it about 6 percent of the fourth dimension.

Note however that if the actual quality of the lot were somewhat worse than i% defective, say v% the probability of accepting these lots drastically to about 29%. This is the situation, we would similar in a sampling plan. If the actual quality is good, then in that location should exist a high probability of credence, just if the actual quality is poor, then the probability of acceptance should be low. Thus in this way the OC curve shows how well a given sampling program discriminates.

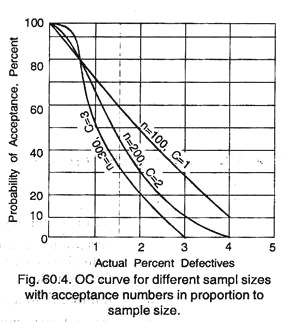

The discriminating ability of any sampling programme depends largely on the size of the sample. Graph 60.four shows the OC curves for sample sizes of 100, 200 and 300 with the acceptance number remaining in the proportion to the sample size. Graph sixty.4 shows that the OC curve becomes steeper as the sample size goes upwardly.

If the discrimination ability of all the 3 plans shown in the graph is compared, it is establish that these would have lots of about 0.seven% defectives virtually 80% of the time (the approximate cross over points of the three curves).

Nonetheless, if actual quality fall to 3 percent defectives, the plan with n = 100 accepts lots about 25% of the time, n = 200 about 10% of the time, and north = 300 less than ane% of the fourth dimension. Therefore, information technology shows that the plans with larger sample sizes are definitely more effective.

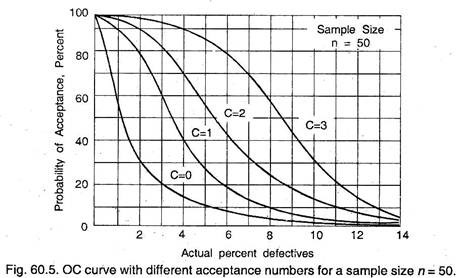

What happens to the OC curve, if whatever of the acceptance number changes? Graph 60.v shows OC curves for sample of n = 50 and acceptance number of C = 0, i, 2 and 3. Graph indicates that the effect is mainly to change the level of the OC bend so that lower acceptance number makes the programme "tighter".

A sampling plan that discriminated perfectly between proficient and bad lots would have an OC curve that was vertical; that is, it would follow the dashed lines of Graph lx.iv. For all lots having percent defectives to the left of the dashed line, the probability of acceptance is 100.

For all lots having percent defectives to the right of the line the probability of acceptances is zero just the but program which could achieve this discrimination is ane requiring cent percent inspection. Therefore, the proper justification for the option of a sampling plan is the balance between inspection costs and the likely toll of rejected parts.

Past making sampling plans more discriminating (increasing sample size) or tighter (decreasing acceptance numbers), we tin approach whatsoever desired level of outgoing quality that nosotros please simply at increasing inspection toll. This increased inspection effort would result in lower probable costs of passing defectives and at some bespeak the combination of the incremental costs is a minimum.

This minimum point defines the most economical sampling plan for a given situation.

O.C. Curves for Double Sampling Plan :

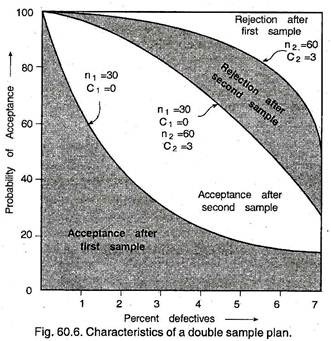

Double sampling plans are generally specified past following:

n1 = number of items in the get-go sample,

c1 = credence number for the starting time sample (i.e. maximum number of defectives that will permit the credence of the lot on the basis of first sample)

due northii = number of items in the second lot

c2 = acceptance number for the 2 samples combined (i.e. maximum number of defectives that will allow the acceptance of the lot on the basis of two samples.

For example, estimation of post-obit sampling plan is given hereunder:

north1 = xxx, c1 = 0, nii = sixty, cii = three

1. Inspect a first sample of 30 items from a lot.

2. Have the lot on the ground of first sample, if the sample contains O defectives.

3. Reject the lot on the footing of get-go sample, if the sample contains more them 3 defectives.

4. Inspect a second sample of threescore items, if the first sample contains 1, 2 or 3 defectives.

five. Accept the lot on the basis of both the samples combined together (thirty + threescore = 90 items), if the defectives are three or less.

half-dozen. Pass up the entire lot on the basis of combined sample, if the defectives are more than 3 items.

Fig. 60.6 shows three O.C. curves involved in the analysis of this double sampling programme.

These three curves separate the effigy in 4 zones indicating following possibilities for acceptance or rejection:

1. I zone (lowest zone)/Credence afterward first sample.

2. Two zone (highest zone)/Rejection after the commencement sample.

3. III zone (lower without hatching zone)—Acceptance afterwards second sample.

4. IV zone (higher with hatching zone)—Rejection after second sample.

Characteristics of the everyman curve is northward = thirty and C = 0.

Characteristics of the highest curve is n = sixty and C = iii.

Characteristics of the centre bend is the actual O.C. bend of the double sampling programme.

Zones of O.C. Curve :

O.C. curve tin exist divided into following iii zones:

(a) Acceptance Zone:

In this zone all the batches are accepted, therefore, the O.C. bend should be so selected that its acceptance zone accepts what is considered to be satisfactory lot.

(b) Rejection Zone:

In this zone, all the batches are rejected. Hence the O.C. curve selected should be such that it rejects what is considered to be an unsatisfactory lot.

(c) Zone of Indecision:

This is the zone where in that location is no purity that whether any particular batch or lot will exist accustomed or rejected. This problem can be solved either by adopting 100% inspection or by taking larger sample, only these will increase the inspection costs.

A batch or lot in this zone is worse than acceptable lot, and meliorate than those what is considered as unacceptable. Thus its quality is border-line, and practically does non matter much whether a lot is finally accepted or rejected from this zone.

Source: https://www.businessmanagementideas.com/production-management/operating-characteristic-o-c-curves/6960

0 Response to "How to Draw Oc Curve for Double Sampling Plan"

Post a Comment